The infill pattern is the shape or design used for printing the infill, and it also has an effect on printing time. How much time this setting can save you will depend on the model itself, so enable the setting and adjust the two parameters, then slice the model and compare the estimated print time to the one without Gradual infill steps. You can adjust two different settings: Gradual Infill Steps, which represents the number of times the infill gets reduced by half, and the Height, which controls the height at which the infill density gets reduced. When using a gradual infill you will obtain a density gradient throughout the entire model, and this will reduce the amount of material used by starting with a low-density percentage at the bottom layers and gradually increasing it near top layers. There is one way to avoid reducing infill density throughout the entire print, while at the same time, mitigating the strength loss. So, in short Lowering the infill density to about 10% could save you anywhere from minutes to a couple of hours per print.

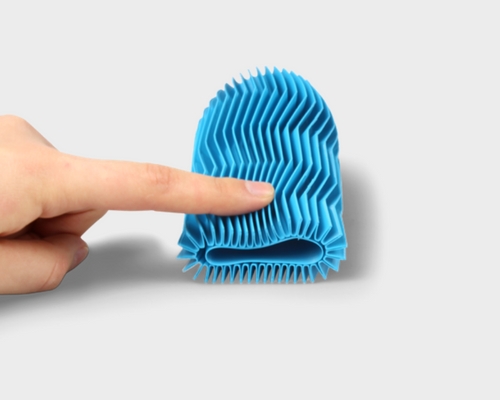

Therefore, if you want to print faster, you should decrease the infill density, but always keep in mind that this could impact the print’s strength. The denser the piece, the greater the amount of material that has to be extruded, and the longer it’s going to take your printer to finish the print. The infill makes up the inner volume of the models, and one of its settings we can adjust is the density, which represents how much, or how little, material is going to be making up the inner part of the model, and it can go from 0%, meaning completely hollow, to 100%, meaning completely solid. In short, reducing the number of perimeters/shells results in faster prints. Reducing the number of perimeters means that the printing path becomes shorter and the amount of extruded material is reduced, thus we get faster print times. For example, setting the wall thickness to 1.2mm means that the printer will print a total of three perimeters (shown as Wall Line Count in Cura) since each perimeter is 0.4mm in thickness. When adjusting the wall thickness, you are automatically setting the number of perimeters. The shell (or perimeter) makes up the exterior of 3D printed parts and can be categorized into two sections: the walls, and the top and bottom. Let’s see the best way of reducing printing times by trying to affect the quality of the print as little as possible: Number of Shells (Wall Line Count)

#Speed up 3d printer software

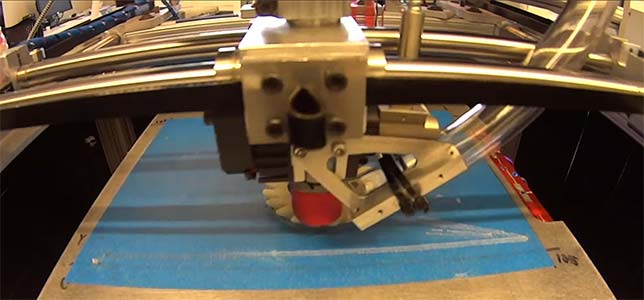

Slicer settings that affect print timeĪ slicer is the computer software responsible for converting a model in STL format into printer commands in g-code format.Īlmost all of these apps allow you to control several parameters, such as infill and perimeters features, layer width & height, speed, etc., and all of them can have a great impact on printing speed. Generally speaking, the faster the print, the lower the quality.

Increasing the nozzle size could yield significantly faster print times but, again, this comes at the cost of quality. Here you have an extended article on the topic. In addition, if the printer is going too fast, the filament may not have the time to create a strong bond resulting in weak layer adhesion. The filament has its limitations too since it needs a specific temperature to get melted and, if the machine moves too fast, this can limit the flow rate due to the machine not being able to melt filament at that rate. This is because fast movements from the extruder could generate significant vibrations. The design and the material from which the machines are made could affect quality at high speeds. The machine’s ability to handle a given speed will be an important factor to consider when evaluating how speed affects printing quality. So, without any further ado, let’s get started! Speed vs Quality

#Speed up 3d printer how to

In this article, I will be going over the different settings you can adjust in your Slicer to significantly reduce the time it takes for a print to finish, how to maintain print quality (somewhat), as well as a couple different tips & tricks to make it all happen. But, is there a way to speed up the process, especially without a reduction in print quality? 3D printing isn’t particularly a speedy process: Some small-ish models can take what feels like an eternity to print (I just printed a model that took 37 hours).

0 kommentar(er)

0 kommentar(er)